Metal-Organic Frameworks, often shortened to MOFs, have quietly become one of the most talked-about materials in modern science. While the name may sound technical, the idea behind MOFs is surprisingly intuitive. These materials are designed to hold, trap, or interact with molecules in a highly controlled way—and they do it exceptionally well.

Over the past two decades, MOFs have moved from academic curiosity to serious candidates for solving real-world problems, including gas storage, pollution control, and even drug delivery. This guide explains what MOFs are, how they work, and why so many researchers are excited about them.

What Exactly Is a Metal-Organic Framework?

A Metal-Organic Framework is a solid material built from two main ingredients: metal atoms and organic molecules. The metal atoms act as connection points, while the organic molecules link them together, forming a repeating, three-dimensional structure.

What makes this structure special is the space inside it. MOFs contain an enormous number of microscopic pores—tiny empty spaces that can hold gases, liquids, or other molecules. In fact, some MOFs have so much internal surface area that just one gram of material can equal the area of multiple sports fields.

Because of this internal architecture, MOFs behave like highly engineered molecular containers rather than ordinary solids.

The Building Blocks of MOFs

Although there are thousands of different MOFs, they all share the same basic design principles.

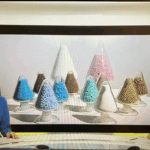

- Metal Centers

These are usually metal ions such as zinc, copper, iron, or aluminum. They determine the overall shape and strength of the framework and help anchor the structure in place. - Organic Linkers

Organic linkers are carbon-based molecules that connect the metal centers. By changing the length or chemistry of these linkers, scientists can control the size and behavior of the pores. - A Porous Network

When metal centers and organic linkers come together, they form a rigid yet open network. This network is what gives MOFs their ability to absorb, store, or separate different substances.

Why Are MOFs Such a Big Deal?

MOFs stand out because they are designed materials, not naturally occurring ones. Researchers can tailor them at the molecular level to perform specific tasks.

Some key reasons MOFs are considered important include:

- Exceptionally high internal surface area

- Adjustable pore size and chemistry

- Ability to selectively capture certain molecules

- Reusability in many applications

This level of customization is difficult to achieve with traditional materials like activated carbon or zeolites.

How Metal-Organic Frameworks Are Made

Most MOFs are created through controlled chemical reactions in solution. Metal salts and organic molecules are mixed under specific conditions, allowing them to self-assemble into ordered crystalline structures.

This process may sound simple, but small changes in temperature, solvent, or concentration can dramatically affect the final material. As a result, MOF synthesis is both a science and an art.

Advantages of MOFs Over Traditional Materials

When compared with older porous materials, MOFs offer several advantages:

- Greater design flexibility

- More precise control over molecular interactions

- Higher efficiency in many applications

These strengths explain why MOFs continue to attract attention across multiple industries.

Read Also: From Nobel Prize Discovery to MOF Technology for Sustainable Energy

The Future of Metal-Organic Frameworks

Metal-Organic Frameworks are no longer speculative materials. They represent a flexible and powerful platform capable of supporting multiple high-impact technologies. The next stage of their evolution depends on thoughtful integration, engineering discipline, and a clear understanding of real-world constraints. CubiTan® reflects this progression. By aligning advanced MOF chemistry with practical deployment strategies, CubiTan® helps define how Metal-Organic Frameworks can function as foundational components in next-generation energy, environmental, and biomedical systems.